Isantya esiphezulu seRoller feeder

Uphawu

Ukuhlengahlengiswa kwamanqanaba kusetyenziswa ukufundwa kwemitha yokubonisa yedijithali;

2.Ukucacisa okuphezulu kwesikrufu kuqhutywa kukuqiniswa kunye nokubi kweendlela ezimbini zendlela yokulawula uhlengahlengiso lobubanzi;

3.Ukuphakama komgca wokondla kulungelelaniswa lilifti eqhutywa yimoto;

4. Isixhobo sokuthintela isixhobo esisetyenziselwa ukuhambisa iphepha;

5. Ukondla i-roller kunye nokulungiswa kwe-roller kwenziwa nge-alloy high bearing steel (unyango olunzima lwe-chromium plating);

6. Isixhobo sokucinezela ngesanti kubunzulu baphantsi;

7. Isixhobo segesi sisebenzisa izixhobo zentloko yokondla yevili lokucinezela;

8. Icebo oluzenzekelayo isixhobo ukondla intloko;

9. Isixhobo sentloko senkxaso yeHydraulic;

10. Inkqubo yokondla ilawulwa yinkqubo yeMitsubishi PLC;

11.Ukuchaneka kokondla kulawulwa yiYaskawa servo motor kunye nokuchaneka okuphezulu kwiplanethi yeservo yokunciphisa;

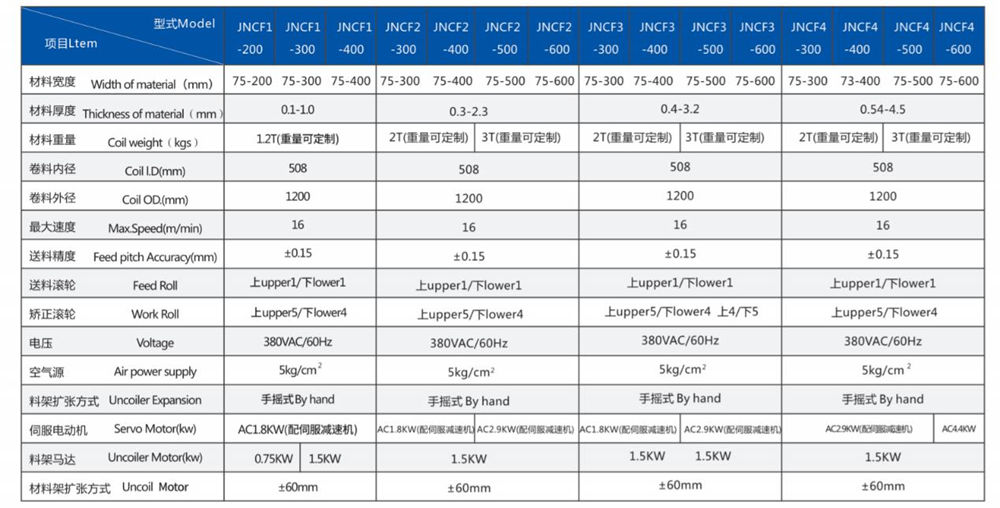

Izixhobo kunye nohlengahlengiso lweservo feeder

Ubume bengingqi

1.Umgangatho ophezulu, i-brushless servo motor drive, eluncedo ukunciphisa umgama wokuhambisa, uhlengahlengiso kunye nexesha lokuvavanya.

2. Ngokucaca okuphezulu kobuntununtunu, ingxelo ichanekile kwaye ukuchaneka kwesondlo kuyaphuculwa.

3. Xa ixhotywe ngebhanti ehambelanayo yokuqhuba, inokuphelisa umsantsa wokuhamba, ukunxiba kancinci, akukho ngxolo, akukho ukuthambisa, ukhuseleko kunye nokusingqongileyo.

4. Uhlobo olufihliweyo lweMada, lunokuthintela ukudluliselwa kunye nokulayisha kunye nokothula umthwalo.

Izixhobo bur ngesantya esiphezulu

1. Kwelinye icala lamanqindi okubetha itafile yomatshini, ukubhola kunye nokugrumba imingxunya emi-4 ngokokubeka icala kwibhodi yezixhobo kunye nokulungisa ibhodi yezixhobo kuyo.

2. Phakamisa icandelo eliphambili ngesilingi, lungelelanisa isitshixo phakathi kwesilayidi kunye nebhodi yezixhobo, kwaye ulungise umzimba ophambili kwibhodi yezixhobo ngezikulufu ezimbini ezifanayo.

3. Xa ukuphakama kunye nokuhamba ngokuthe tyaba kwesondli kungangqinelani nokugxothwa kwedini, ipleyiti yesilayidi yeNC feeder inokuhlengahlengiswa malunga ne-100 mm. Ngeli xesha, iibholiti ezimbini ezikwipleyiti yesilayidi zinokukhululeka, kwaye iibholiti ezinziweyo kwibhodi yezixhobo zinokulungiswa. Emva koko, icala elithe tyaba le feeder linokutshintshwa. Emva kokufikelela kwindawo efanelekileyo, izikrufu zinokuqiniswa.

4. Lungisa isikhunta ukuze kuqinisekiswe ukuba ulwalathiso lwesikhombisi kunye ne-roller luthe nkqo, kwaye izixhobo ezikwibhokisi yesilayidi yenqindi zinendawo efanelekileyo yokuphumla. (Qaphela: ukuba kukho umgama phakathi kwepleyiti yenkxaso kunye ne-die esezantsi xa unyathela izinto ezincinci, kuyafuneka ukufakela izixhobo ezikhokelayo ukwenzela ukuba ungenzi idatha inyanzelise, kwaye ukungunda kufuneka kulungiswe ngokuthe ngqo ngeroli, Ngaphandle koko idatha iya kutshintshwa, isondli iyaxhathisa, kwaye umgama wokondla uya kugxadazeleka.)

5. Ibhokisi yolawulo lwombane kunye nokutshintshela kufutshane kufuneka kufakwe kwindawo efanelekileyo yomatshini wokubetha, kunye nokusebenza okuqhelekileyo kwebhokisi yolawulo lwombane kunye nokutshintsha kufutshane kufuneka kuvavanywe.

Ukuyalela umzekelo wovavanyo

1.Qalisa umatshini wolusu okanye i-rack yokuhambisa izinto kancinci kancinci.

2. Ngokobubanzi bezinto, lungisa uhlengahlengiso lwamavili amabini okugcina, angathinteli ukusebenza kwedatha.

3. Beka isiphatho sokukhulula eqongeni, beka imathiriyeli phakathi kweeroli ezisentla nezisezantsi, yehlisa isiphatho sokukhulula, ukhulule isikrufu esisisigxina sesiphatho sokulungelelanisa ubukhulu bezinto, lungisa isiphatho phezulu nasezantsi, ukuze isibiyeli sokukhulula sibe isithuba esivulekileyo esimalunga ne-5mm, emva koko sitshixe isiqwenga sokulungisa isiphatho. (Qaphela: ukuba akukho sikhewu kubakaki bokukhulula, idatha ayizukucinezelwa ngokuqinileyo kwaye ityibilike, ukwenza i-feeder kungavumelekanga. Xa ubukhulu bedatha butshintsha, kuyafuneka ukuba uhlengahlengise kwasekuqaleni).

4. Xa izinto zicofiwe, loo nto ayizukucinezelwa ngeroli.

5. Emva kokusetha ubude be-feeder, kuxhomekeka kwimeko eyiyo, setha isantya se-feeder ngokufanelekileyo. Indlela yokumisela iya kuqaliswa ngeenkcukacha kamva.

6. Emva kokuba iiparameter ezifanelekileyo ze-feeder zibekiwe, ubude be-feeder abufani nexabiso elimiselweyo ngenxa yenani eliqikelelweyo. Ke ngoko, ubude obusebenzayo be-feeder kufuneka buhlengahlengiswe ngokungqinelana novavanyo lwe-feeder, i-punch, stroke, ukunyathela kunye nohlengahlengiso kwimowudi yemanyuwali.

7. Xa umphezulu wesikhonkwane sesikhombisi ungena kumngxunya wesikhonkwane sesikhombisi, intonga yokujija inokuhlengahlengiswa ukuze ichukumise ukuthwala kwenkxaso yokukhulula kude kuyekwe ukukhululeka kwezinto, kunye ne-screw nut itshixiwe (ukukhululeka komoya feeder, indawo yokukhulula kufuneka ilungelelaniswe ngokufanelekileyo.

8. Uhlengahlengiso lwendawo yokuqala yokondla luhlengahlengiso yikhamera yokujikeleza yeendaba. Oko kubizwa ngokuba ngumqondiso wokuqala wesondli kubhekisa kwindawo yokujonga yomphambili wepunch ukuqala ukondla. Indawo yokujonga eyondliwayo yeyokuqala ngo-9: 00 ukuya ku-3: 00.

9. Emva kokumisela, kufuneka ukuba kuvavanywe ukubetha kuqala kuqala, emva koko imveliso eqhubekayo inokuqhutywa emva kohlengahlengiso.